3D Printing

Home > Learn > Tech > 3D Printing

What is 3D Printing?

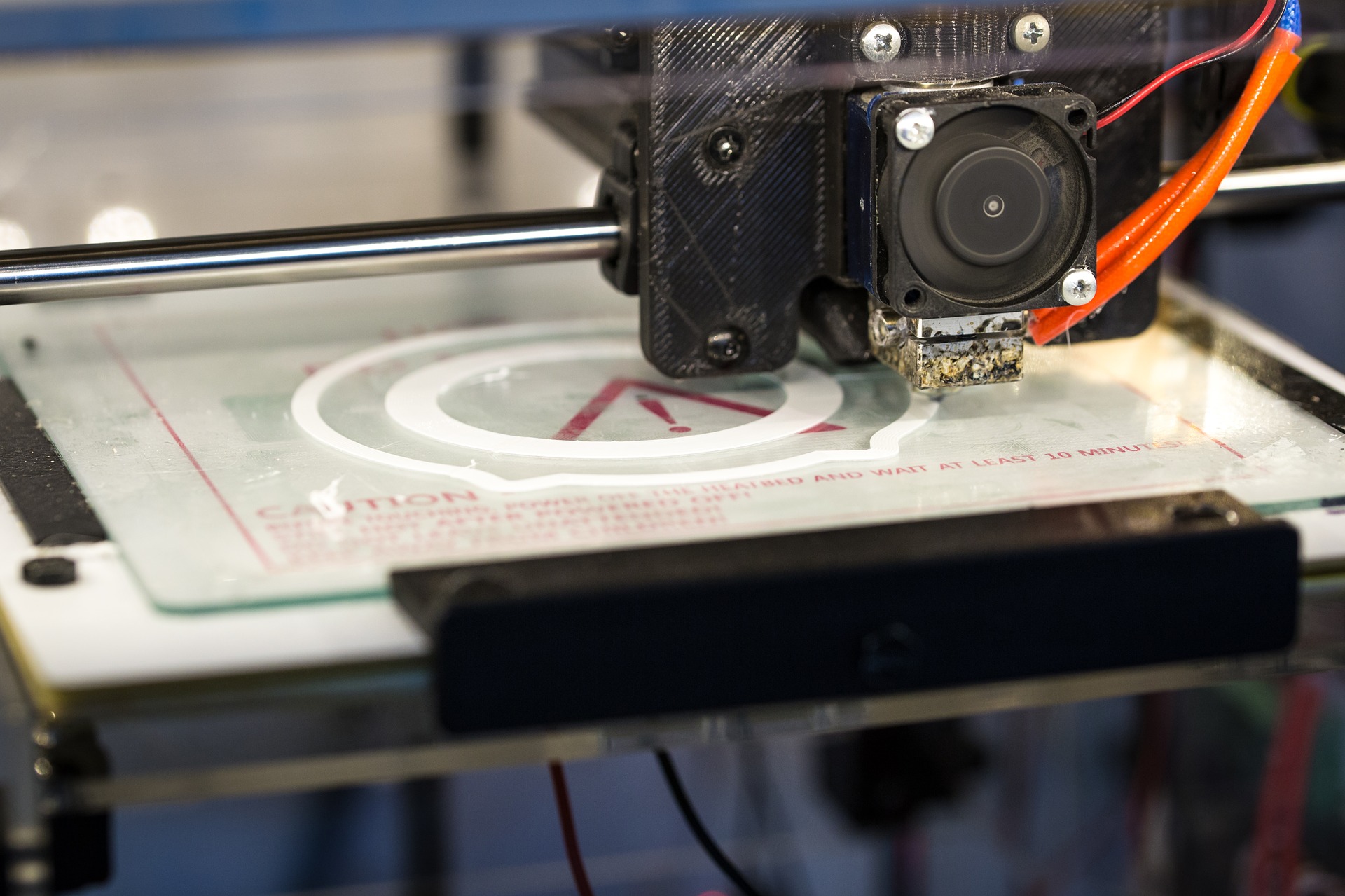

3D printing is the production of a physical model or object using an additive manufacturing process from a computerized model. Most 3D printers make thin layers of plastic or resin (though metal 3D printers are out there in industry) which build up to create the finished piece. While this process can be slow, it doesn’t have to be constantly tended.

This can be a surprisingly useful method for the creation of anything from trinkets and toys for hobbies to small replacement parts or even the design of whole new products for business. There are some items which are only possible through the additive manufacturing process because you can print hidden mechanisms within a piece.

Use Examples:

- Miniature gaming figurines

- Costume parts for cosplay

- Toy models (Including RC model planes, cars, drones, and rockets just to start)

- Functional tools

- Replacement plastic parts

- Functional items around the house

- Models for use in metal casting

- Pattern-making

- Rocket nozzles

- Jewelry designs

- Computer gadgets

- Home defense items

3D printers can run anywhere from $120 to thousands and thousands, depending on the size and capabilities of the machine. Most hobbyists can get a decent quality functional printer for $200 and with freely available software design almost anything you can think of. The process of designing the objects has a definite learning curve, but can be a highly useful skill for years to come.

What is 3D Manufacturing?

Similar to 3D printing, this generally starts as a computer file that you design or download. The difference is that in most 3D manufacturing, it is a subtractive process where you start with a solid chunk of material (wood, plastic or metal) and use a CNC machine to rout away slivers of the material until what you’re left with is the desired part. These machines can be incredibly precise and can produce fully functional parts out of even steel and titanium. Other 3D types of CNC manufacturing include CNC Routers for plywood or regular wood, Laser engravers and cutters, and CNC lathes.

The files and processes used in 3D manufacturing are quite similar to those used in 3D printing, but there is still quite a learning curve to get proficient. Put in the time and effort and you can make almost anything you could possibly need.

While the starting price in this realm is higher than 3D printers, there are still very high quality machines available for home use on the new and used market for under $5000 which could literally be used to start a new business.

Use Examples:

- Product Design and Development

- Signage Design and Creation

- Home decor (wall art, serving platters, cutting boards)

- Woodworking items that require repetition of parts

- Robotics

- Automotive part design

- Aerospace design

Getting Started with 3D Printing

Which Printer to Buy?

Most people should start with an inexpensive FDM printer (for small to moderate sized functional items up to 12″ wide) or resin printer (for tiny to small, but highly detailed). There are actually decent, reasonable options in the $150-250 price range for this. FDM printers use spools of plastic filament (commonly PLA, ABS, PETG or Nylon) which is pulled through a heated extruder and melted onto a print bed, then built up layer by layer. Resin (SLA) printers are usually smaller but higher resolution and use an LCD screen with a ultraviolet backlight which cures UV-sensitive resin layer by layer.

FDM Starter Printer Suggestions: Creality Ender 3 (8.6″x8.6″x10.6″ print volume ~$200) Elegoo Neptune 2 (8.6″x8.6″x9.8″~ $200)

Resin Printer Suggestions: Elegoo Mars 2 Pro (3.1″x5.1″x6.3″ print volume ~ $290) or Mars 3 (3.5×5.6×6.8 ~ $300) Anycubic Photon Mono (~ $215) 3″x5″x6.5″ print volume

Keep in mind there are hundreds of reputable 3D printer manufacturers and most of these printers in the low price range are functional but may benefit from upgrades. While it’s not necessary to come into the hobby with an electronics-nerd mindset, it certainly doesn’t hurt as this may be an opportunity to learn soldering, single-board computing, and since 3D printers are technically robots – robotics! On the other hand, if you have something specific to accomplish in mind, it may be worth it to spend a few hundred dollars more and get a model which includes more features such as a larger bed, heated bed, upgraded extruder (which can allow different materials) or quicker printing.

Software

- Autodesk Fusion 360 (free for hobbyist use)

- The Blender project – Free and Open 3D Creation Software

- You can also use most any 3D software, depending on your needs for precision as most will allow you to export as an STL file, which is what you need to print (or machine)

Miscellaneous

- On the group we have a number of people who are active 3D printers and are happy to help you on your 3D printing journey, sharing tips, tricks and helping others get started.

- If you would like something 3D printed, but don’t want to go through the process of learning it yourself, you’ll likely find somebody interested in helping, so feel free to ask!